Are we ready for the next industrial revolution?

Aleksandra Banaś, CEO of ifm electronic, addresses the challenges of Industry 5.0, the problems of the Polish industrial sector, and its prospects and directions of development.

Aleksandra Banaś, CEO of ifm electronic, addresses the challenges of Industry 5.0, the problems of the Polish industrial sector, and its prospects and directions of development.

WBJ: At what stage of the road to the 5.0 revolution are we on? From your observations, are we ready for the full integration of human and artificial intelligence?

I believe that the Polish industry is mentally ready for the 5.0 revolution, but if we consider technology and the digitalization of businesses, we are still stuck in the 4.0 revolution, and sometimes even the 3.0 one. From month to month and year to year, we can see the growth of innovation in areas such as the Internet of Things (IoT), automation, or robotics. However, it is still common that a human steps in when a computer fails. In some companies the economic aspect often plays a more significant role, and human labor is sometimes more profitable in financial terms. Additionally, it is easier to buy a modern machine than to find a properly trained employee to calibrate and repair it. The full integration of people with machines will take time. It requires the education and training of human resources, and this is a time-consuming process. Evolution is happening right before our eyes, but the revolution is still some time away. Everything is moving in the right direction, but despite the goal-oriented attitude, we often feel a sense of resistance to change and fear that artificial intelligence will take away our jobs. Personally, I love change and actively promote innovation at ifm electronic. However, in this case, these changes will take time, an openness to action, and permission to make mistakes and take risks.

Is ifm electronic ready for the 5.0 revolution?

I don't consider our work in terms of further revolutions, which will eventually happen in one way or another. Our goal is to do our job as well as we can. I often feel that we all get breathless constantly chasing an ideal state, which in the VUCA world is rather impossible to achieve. Technology supports us, and we use it as much as we can. However, humans have to agree that technology not only supports us but also co-creates our reality. Sooner or later, we will have to start living in symbiosis with technology but for now, let's enjoy its benefits as much as we can, using the available resources.

What KPIs do you consider when assessing a company's readiness to enter the next level of the industrial revolution?

I am not a fan of evaluating anything through the prism of KPIs. Of course, metrics are helpful because they show the effectiveness of implemented processes, structures, positions, or solutions. But I shy away from evaluating a company's readiness "for tomorrow" through the prism of rigid metrics. It is more important to involve our team, implement new ideas and experiment rather than just measuring and comparing indicators. I believe that it is the synergy in human activities that allows us to go to the next level in every area.

You mentioned that sometimes buying a machine is easier than finding a properly trained employee to fix it. Education is one of the challenges facing the human factor. It is certainly not the only one.

Working with people allows me to observe their approach to new technologies. My team invariably amazes me with their skills, competence, and how they use digitalization. I think that if someone is open to new things, they can learn everything. Sometimes we don't want to get involved because we trust ourselves more than we trust machines. We don't know what role technology will have in a few years and whether it will sometimes want to take our place. Concerns in my opinion, are not valid, but I understand them. Among the competencies of the future, I would certainly mention the ability to act in situations of uncertainty, to cooperate with others, to be creative and to feel (and take) responsibility. In a changing world, these are essential to thrive.

Automation, robotization and digitization are already happening, but we are far behind world-class manufacturers in terms of Overall Equipment Effectiveness (OEE). They have an OEE of 85%, while we have a maximum of 65%. Where does this come from?

I believe the reasons for the lower efficiency of machines in Polish factories are due to the fact that we had a different start than most countries in the world. However, we are still catching up! Our engineers and maintenance staff are real diamonds, and I'm convinced that they are up to the challenge - whether it's keeping machines and equipment running, energy efficiency, or enhancing productivity.

How does ifm support the improvement of machine efficiency at its customers?

As a supplier of systems and automation to industry, we can do what we do best: provide tools and solutions that support our customers’ decisions, turn their visions and ideas into tangible actions and help improve production performance. The rest is up to them.

Putting aside the issue of production itself, how do ifm's hardware and software solutions support sustainability?

At ifm, we start from the premise that all participants in the supply chain must work together to take concrete steps towards sustainability. That's why we are already using AI tools to optimize profits and minimize losses in the industrial sector. For example, our moneo platform converts sensor data into digital information, enabling predictive maintenance of machines, avoiding unplanned downtime, and increasing the efficiency of the entire plant. Our technologies also allow early detection of serious damage, reduce unnecessary downtime, or enable real reductions in waste production. Given the nature of our products, we must feel a shared responsibility and support our customers' ESG activities. I don't see any other option.

What are ifm's development plans for the coming years? Are you going full steam ahead, or still proceeding cautiously due to uncertainties in how supply chains will evolve?

There is no reason to stay in limbo indefinitely. What is supposed to happen will happen, whether we proceed cautiously or not. Therefore, we are going full steam ahead! But after the recent crises, we are also weighing the risks and trying to balance them with a bit of prudence and reason.

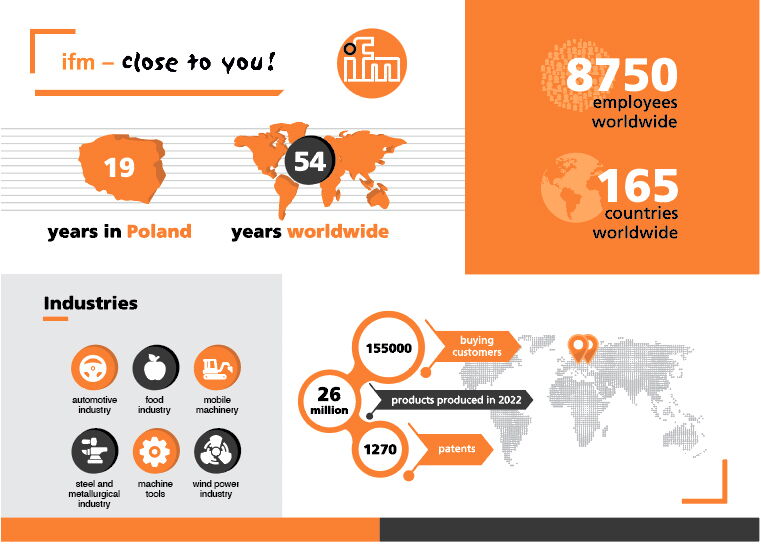

Aleksandra Banaś has been the CEO of ifm electronic sp. z o.o since 2013 and has been with the company since 2004. She has dedicated many years of intensive work to the development of the company in the Polish market, and under her leadership, ifm has received numerous awards and distinctions. With a passion for innovative solutions in the industry, she is always seeking opportunities to connect the world of automation with the world of IT.

Since its establishment in 2004 with just four employees, ifm has grown significantly, now employing over 30 people and holding a crucial position in the Polish industrial automation market. The company specializes in developing sensors, controllers, software, and systems for industrial automation across all industries where automation is possible.