WBJ: Nineteen years at the same company is a long time. You could say that you know ArcelorMittal Poland inside out, and this year the company celebrates 20 years in the Polish market. It seems that you have accompanied the company on this long journey from the very beginning. How do you remember it?

Sanjay Samaddar: Indeed, I have had the honor and privilege to be associated with ArcelorMittal Poland, in a leadership role, for 19 of these glorious 20 years, which we are celebrating this year. Looking back on those two decades evokes fatherly feelings in me. I am a father of two but I feel, and I know, that this company is my third child, one that has also grown into adulthood.

Over the last two decades, we have put a lot of effort and commitment into maintaining and developing the steel industry in Poland, far exceeding the commitments of the privatization agreement and continuing investments despite crises, market volatility, and aggressive imports from third countries. We have already invested over PLN 10.5 billion in our six facilities, reduced CO2 emissions by 42 percent, dust emissions by 90 percent, and energy consumption by 40 percent. Safety continues to be our top priority. We have reduced the lost time injury frequency rate fourfold since 2004.

According to the latest report from the Warsaw School of Economics, last year ArcelorMittal was the second largest foreign investor in Poland. This is the best evidence of the scale of our engagement. These achievements are especially significant as many steel companies in the CEE region are facing serious challenges, with questions surrounding their continued of operations.

Simply said, in one sentence, I will remember these two decades as a ferocious and successful effort to transform the steelmaking technology in Poland—something I am very proud of.

ArcelorMittal Poland is a leading steel producer in Poland, but not everyone knows what is produced in steel mills and processing plants, where these products can be found, or whether they are still necessary in our lives. With new technologies and AI coming to the forefront, young people are increasingly uncertain about the role and importance of steel.

Steel is the fabric of life; it’s with us from dawn to dusk. Can you imagine your life without it? Imagine a kitchen without a cooker or a fridge. Imagine staying in touch with your loved ones without a mobile phone or getting to them without proper transport—bikes, cars, trams, buses, trains. Imagine… The modern economy also depends on steel. Steelmaking creates jobs not only directly in production—each job in steel generates six jobs in related industries. It’s a driving force in Polish industry: every million zlotys generated in the steel sector produces nearly six million zlotys across the economy. Our strategic business partners are some of the strongest pillars of the Polish economy, including JSW, PKP Cargo, Orlen, and Tauron, just to name a few. It is an honor for us to cooperate with such important players in the Polish market. We believe, our combined partnership and continued response to market needs translates into economic growth and puts wind in the sails of the entire country.

Steel is everywhere around us, yet few people realize that it is a key material and the foundation in many sectors—not only in the past, but also today and into the future. Importantly, steelmaking is no longer just mechanical work. Modern metallurgy must go hand in hand with new technologies.

ArcelorMittal Poland constantly introduces innovative solutions in its plants based on automation, robotization and digital technologies, and uses big data, the Internet of Things (IOT) and artificial intelligence to optimize production processes. We implement Industry 4.0 technology to improve production processes, supply chains and, most importantly, increase occupational safety. We are constantly improving our processes and introducing devices that help us reduce the workload of employees and optimize production, like the MultiWrapper robot that packs cold-rolled, galvanized and organic coated coils in plants in Świętochłowice and Kraków, which allows us to wrap 20-ton steel sheet metal coils in just four minutes. We know that automation is one of the elements that increase the competitiveness of our company on the market, but we know also that we cannot forget that, regardless of the level of technical advancement and robotization, experience, competency, and the knowledge of our employees remain an extremely important factor determining the success of our company.

In summary, I would say that the modern steel industry—which we are in Poland—provides young achievers the excitement of working with cutting-edge technology across a vast range of applications. However, the very fact that you ask this question, is an inspiration for me to work harder to reach out to the new generation to encourage them not to miss this opportunity!

Right, employees. Is it easy to find good employees in such a demanding profession as steel production and processing? Are you lucky to have such a good team?

When ArcelorMittal entered the Polish market in 2004, we knew that the steel plants located in the south of our country were blessed with a local supply of coal from Poland’s rich mining heritage and nearby sources of iron ore—making our plants in Silesia ideally situated for efficient steel production. We discovered very quickly that here, in Poland, steel can be found not only in the steel plants, but also in the character of its people. At our plants, among our more than 9,000 employees, we have many families: sons and daughters working alongside their fathers and mothers, and grandchildren continuing the traditions of their grandparents. Steelmaking is more than just a job. What lies at the heart of our operations is the belief in the meaningfulness of our work. I am sincerely proud of the fact that our teams are not only committed to steel, but also genuinely passionate about it!

The steel industry, like many other segments, is changing, striving to decarbonize and automate processes. That is why continuous improvement and training are so important. At ArcelorMittal Poland, this aspect is very important, we focus on ongoing development and re-skilling of our employees. We offer our employees not only the opportunity for personal development and skill enhancement, but also a wide package of benefits, such as company kindergartens, medical care, a rich social fund, and an employee pension program.

We strive to ensure that our employees continue with us for years, that they want to work with us, that they feel good here. We value their knowledge, experience, intelligence and dedication—qualities that are rare and invaluable today, which is why they are so important to us. This is a fact: we would not be where we are today without the commitment of our more than 9,000 employees, the loyalty of our customers or the openness of our suppliers and authorities—both at the local and national level—as well as cooperation with our social partners, who have always supported our long-term vision for the company.

As a closing remark on this topic, and you may be surprised to hear this from me: we do not need to “find” good employees, because we have plenty of them, and most of them stay with us until retirement! Our mission is to ensure that we do not lose these passionate and skilled people who we are very fortunate to have with us.

You mentioned the challenges of decarbonization. For the steel industry, this is a huge undertaking. How do you plan to achieve it?

The ArcelorMittal Group aims to achieve carbon neutrality by 2050. Decarbonization is a huge challenge for the steel industry across Europe. For it to be successful, several conditions must be met, including: access to large-scale, renewable energy at competitive prices. We know that the transformation will be a long-term process, so we are working intensively to limit our impact on the environment today, in our current processes.

Now we are implementing steps in addressing our asset base, technologies, and processes to meet our decarbonization targets. But transforming our steelmaking assets will not suffice, the energy used in the steelmaking processes will also need to undergo transformation. Steel can be produced via two routes: the traditional Blast furnace route, and the more modern Electric Arc Furnace (EAF) route. The former relies on the use of iron ore with coke as fuel. This route is far more carbon intensive than the EAF technology, which relies on the use of scrap and electricity at competitive prices. Perhaps the first step on the steel industry’s decarbonization journey will be the switch from the Blast furnace route to the EAF route. In the longer term, as industries advance towards climate neutrality, there will be a need for clean electricity and green hydrogen, which will be needed in large amounts. We will also need support at the national and European level, because this is a big challenge that cannot be met alone.

Steel must decarbonize, because it is the foundation for the decarbonization of other sectors. We are part of the solution for the utility companies—steel is applied in photovoltaic panels, transmission networks and wind turbines. In fact, steel and iron account for 90 per cent of a wind turbine’s weight.

My closing remark to your question on decarbonization is: we feel responsible for the change, and with appropriate support from governments and institutions, we want to be seen and remembered for being part of the solution!

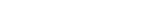

Sanjay Samaddar

Chairman of the Board of Directors at ArcelorMittal Poland, Chief Executive Officer of ArcelorMittal Europe Long Products, Vice President of ArcelorMittal

Throughout his career at ArcelorMittal since 2003, Sanjay has held the positions of CEO, Chairman and Supervisory Board member of ArcelorMittal’s plants in Poland, Romania, Czech Republic and Germany.

Apart from leading mega scale steel operations, he has also headed HR, IT and shared services at ArcelorMittal Europe’s Flat Products division, with more than 40,000 employees in 7 European plants. Since January 2022, Sanjay has been the CEO of ArcelorMittal’s Long Products business in Europe – operations with over 10,000 employees. He is also a member of the Group Management Committee of ArcelorMittal.

Sanjay has been involved with ArcelorMittal Poland since 2005, holding the positions of CEO and Chairman of the Board. During his tenure, the company has invested PLN 10.5 BLN in its assets, significantly reducing its environmental footprint. He has developed a strong bonding with the industrial and cultural landscape of Poland, which has won him numerous awards and recognitions.

Before joining ArcelorMittal, Sanjay spent 19 years in the aluminum industry in India in senior leadership positions involving assignments with Indian Aluminium Company, Hindalco and Vedanta, including the position of CEO of India Foils Limited.

Sanjay has lived in Krakow since 2005. He has a son and a daughter, who are pursuing higher education and working careers in the UK. His wife, a software engineer by profession, is engaged in several social and cultural activities in Krakow.

Read More About ArcelorMittal Poland

Without Steel, There is no Sustainability

Forging the Future: ArcelorMittal Poland Celebrates 20 Years of Excellence